Services

Materials we work with:

- ASTM A787 Aluminized Steel

- 409 Stainless Steel

- 304, 316, & 321 Stainless Steel

- Carbon Steel, Hot Roll, Cold Roll, DOM

- Schedule 40 Pipe

- Solid Round Bar

- Aluminum

- Custom extrusions

- Square tubing

T-Lane Industries knows product quality matters. We feel quality and integrity go hand in hand. It’s why we focus on each customer and earned our reputation as a reliable tubular solutions company.

Our quality process begins by developing a plan for every part.

We evaluate all customer requirements to assure material standards are met and that parts are fabricated to spec.

During fabrication quality is monitored through document control, calibration and inspection, from start to finish. Systematic process audits not only ensure compliance, but they also proactively identify places to improve efficiency and reduce waste. Improvement projects increase customer satisfaction and decrease costs.

Tubing is sourced from approved suppliers to certified standards. All materials are traceable entirely from supplier to customer and documentation is available at request.

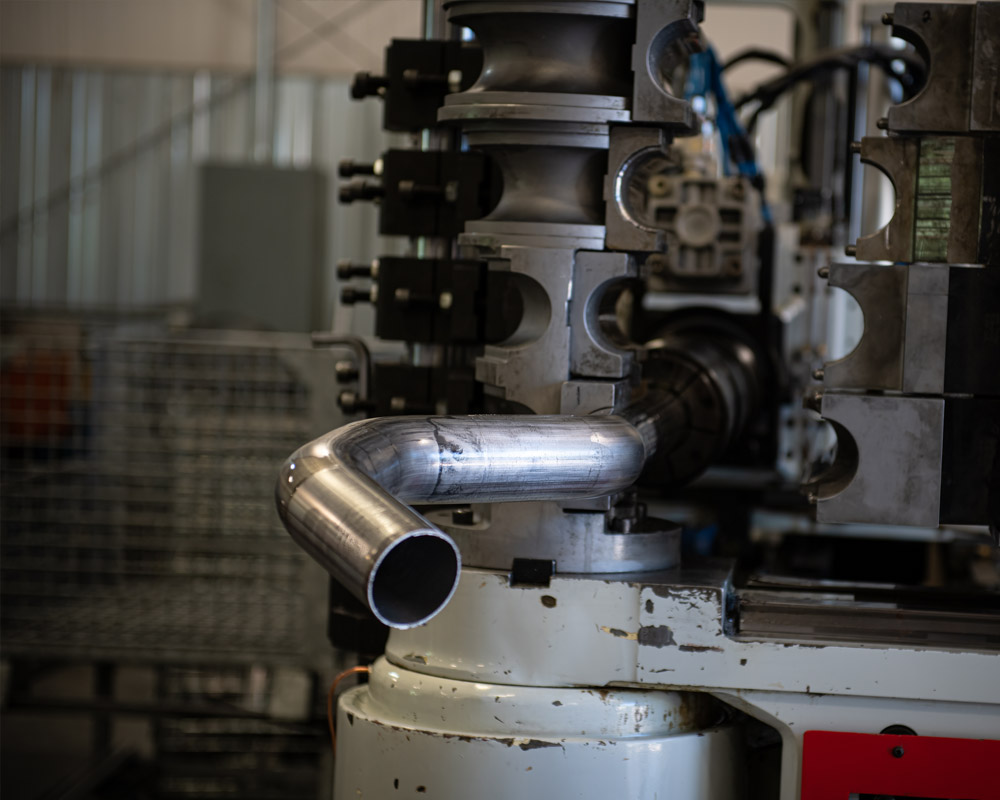

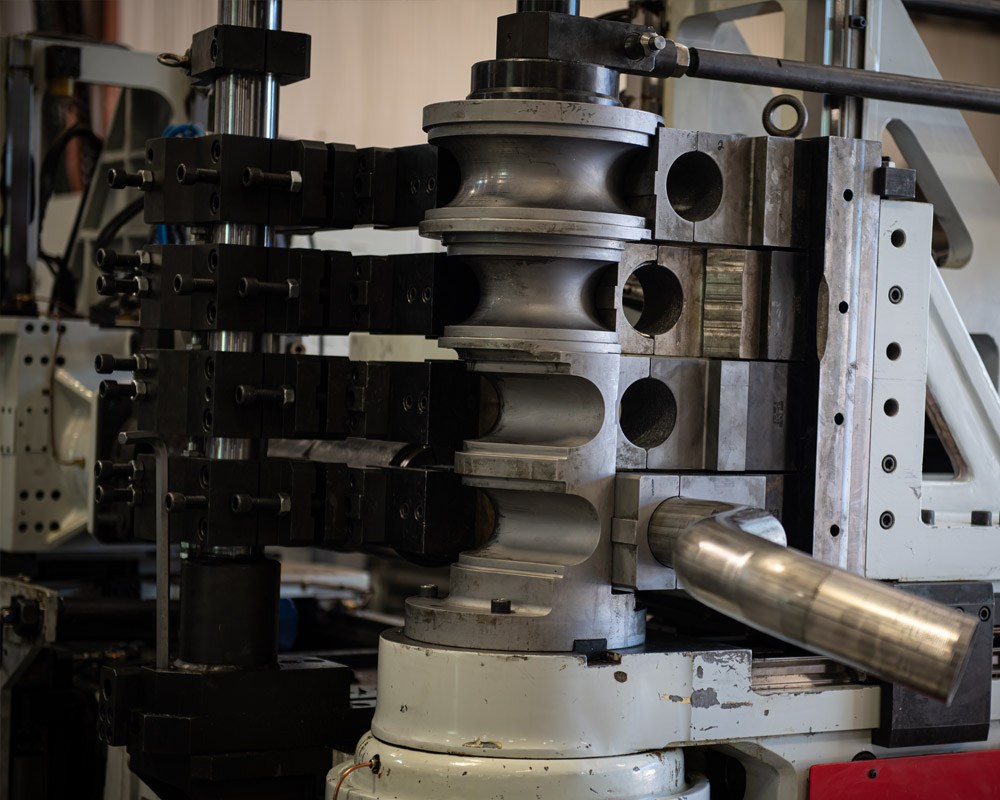

Tube Bending

Custom tube fabrication to your specifications completed by knowledgeable, experience personnel.

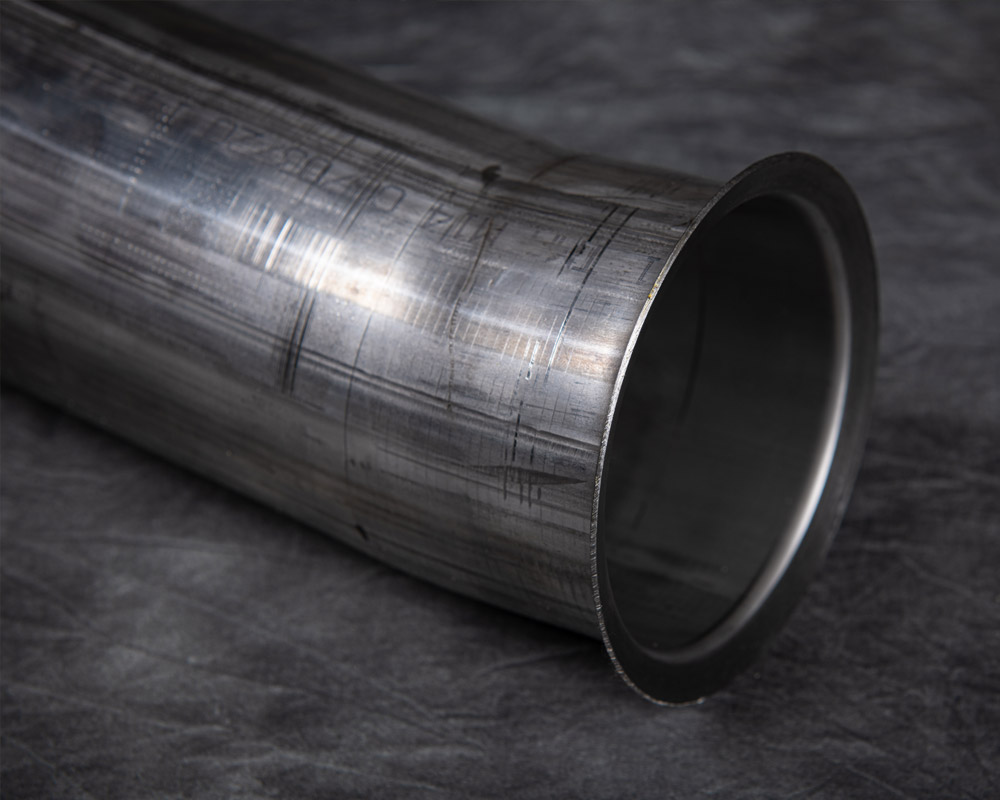

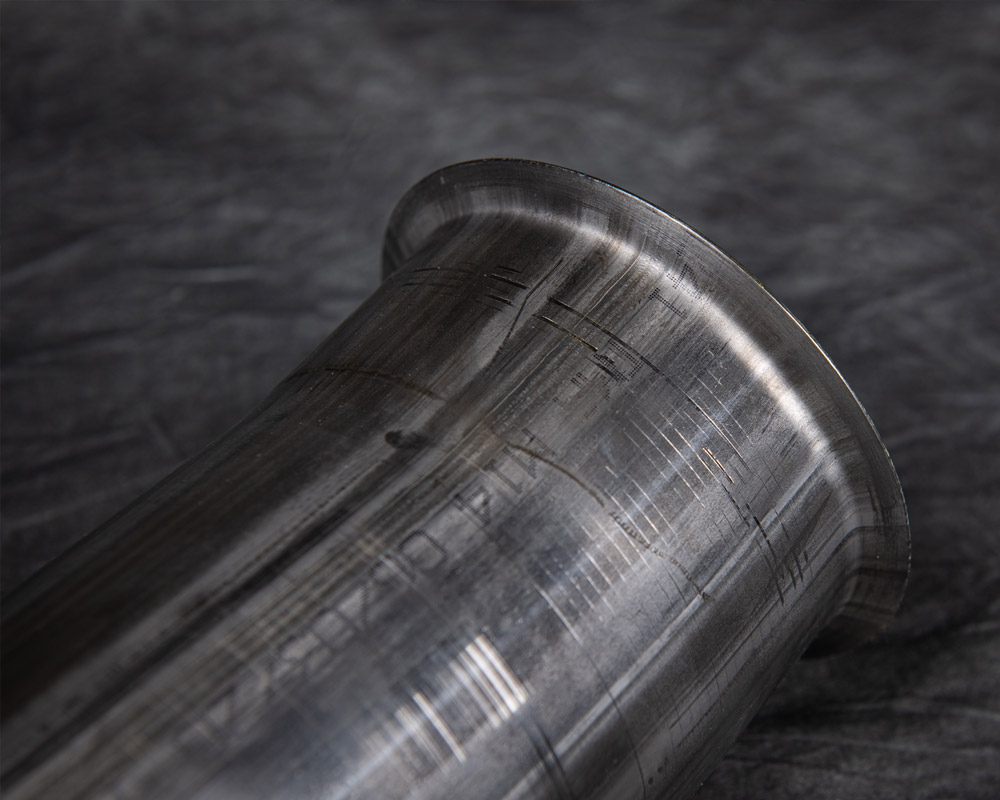

End Forming

T-Lane Industries provides end forming methods that optimize efficiency for automotive parts, piping, and more, providing you with high-quality, reliable components.

Prototype & Reverse Engineering

Need pre-production prototypes? T-Lane Industries can create a prototype through CAD, in house design or through reverse engineering. We can create or recreate parts.

Welding

Skilled MIG and TIG welding processes, whether it be for high aesthetics, hand crafted, or production level welding. We offer cost-effective welding services for hot and cold rolled metals, stainless steel & aluminum.